Industrial Technology: Revolutionized Modern Industries

Industrial technology has brought new dimensions to how the industries function. This metamorphosis is primarily on account of creating an innovative and efficient new landscape for manufacturing, distribution, and production operations. As businesses take on board these modern developments, the benefits have cascaded down to include increased productivity and effective systems.

Smart Manufacturing and IoT

Smart manufacturing has been a formidable tool for the industrial sector. That is, with the Internet of Things, machines, devices, and systems get to communicate and transfer real time data. Connecting everything makes decision-making easier by helping minimize errors and cut costs. With IoT and AI, predictive maintenance could ensure that machinery runs at optimal efficiency and is available for as much time as possible.

Industry 4.0 Technologies

With industry 4.0 came the very latest technologies like robotics, 3D printing, and artificial intelligence. Robotics is slowly replacing assembly lines, giving them the benefit of somewhat better precision and speed. 3D printing fast-tracks prototyping and bespoke production. Big data analytics also helps in improving operational efficiencies by providing insights that can guide better strategies and results.

Sustainability in Industrial Technology

Sustainability is slowly becoming a major approach in industrial technology. Energy-efficient machines, renewable energy solutions, and a whole array of waste-reduction technologies are enabling industries to cut down their overall environmental impact. Green manufacturing is introducing a culture of environmental consideration without diminishing the production output.

Cybersecurity in Industrial Systems

As industrial operations continue getting more digital, cybersecurity is now critical. Protecting sensitive data and systems from cyber threats is critical to maintaining operations and protecting valuable assets. Advanced security protocols and AI-driven monitoring systems are the most common in adoption across industries.

Industrial technology continues to influence industry into the future by bringing about innovation, efficiency, and sustainability, serving thus as a crucial component of modern commercial strategies.

It is expected that these technologies would integrate gradually into the totality of industrial technology.

1. Automation and Robotics

Industrial technology heavily uses automation and robotics to increase efficiency, precision, and productivity. These technologies reduce human error and increase output in industries.

2. Manufacturing IoT

Due to IoT technology, industrial processes are revolutionized from real-time monitoring and predictive maintenance to seamless interactions among machines.

3. 3D Printing

Additive manufacturing or 3D printing allows industries to make prototypes, tools, and even final products quicker and cheaper than traditional methods.

4. Sustainable Solutions

Industrial technology is geared toward producing highly eco-friendly innovations such as energy-efficient machines, waste-reduction systems, and green manufacturing techniques whereby industries can meet their sustainability goals.

5. AI and Machine Learning

Integration of artificial intelligence or AI and machine learning into industrial systems promotes smarter decision-making, better forecasting, and optimized operations.

6. Cybersecurity in Industrial Systems

As industries adopt digital technologies, cybersecurity solutions became quintessential to avoid the threats of cyber-attacks against sensitive data and infrastructure.

7. Digital Twin Technology

The digital twin concept-the virtual replica of a physical system-enables simulation, investigation, and optimization of processes in industries, thus reducing downtime and costs.

8. Advanced Material Technology

Advancements in material science such as lightweight composites and smart materials enhance the durability and functionality of products produced across industries.

9. Industrial Drones

Drones are being used for aerial inspections, mapping, and surveying in an industrial setting where time and accuracy are critical.

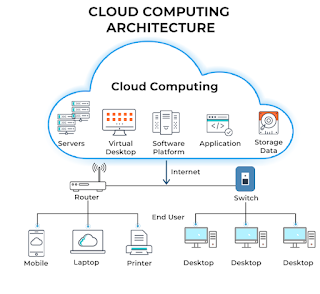

10. Cloud Computing

Cloud solutions allow industries to securely store, analyze, and access data that further helps in improving interaction and decision-making.

Integrating the technologies is shaping the future of manufacturing and operations.

1. Manufacturing technology

The Fourth Industrial Revolution-a transformative trend in manufacturing technology-combines the Internet of Things (IoT), artificial intelligence, and data analysis. This provides manufacturing with smart insights on production lines by assessing machine performance and enabling predictive maintenance to minimize downtime. By incorporating data into the manufacturing process, such systems will keep streams optimizing, condensing time waste, and increasing the precision within such processes.

3D printing or additive manufacturing changes the manufacturing landscape by allowing manufacturers to produce intricate prototypes of components and final-use products overnight with ease and at a lower cost. Its flexibility is capable of disrupting such varied industries as aerospace, automotive, and healthcare, where customization and rapid prototyping are paramount.

Robots and automation are reducing repetitive tasks, improving safety, and increasing productivity. The use of collaborative Robotics rapidly growing in manufacturing and could work in tandem with human employees, improving efficiency without eliminating jobs.

Sustainable development is further compounding the drive toward innovation in manufacturing. Energy-efficient machinery, renewable-energy incorporation, etc., are certainly going to be conducive to businesses enhancing profitability while harnessing freedom from pollution.

Thus, the merging of all those developments can keep the manufacturing space intact, competitive enough in such a fast, changing global market. As development moves forward, the future of manufacturing is destined to become smart, sustainable, and efficient.

The integration of such technologies can actually help manufacturers to keep pace with a fast-changing global environment. The future of manufacturing, as improvements continue, is most likely to be smarter and thus more sustainable and energy efficient.

Preferable, the time to be wise and embrace the necessity of the incorporation and modernization of one's manufacturing processes is not in this frame anymore. Think ahead as one strives to keep ahead for success within the context of the digital transformation.

2. The Application of Automation and Robotics

In this rapidly moving epoch, automation and robotics are transforming industries, thereby forming a future that should be marked by efficiency, innovation, and utmost convenience. Technology continues to drive change across industries-from manufacturing to healthcare-by speeding up procedures, ensuring accuracy, and driving human effort off the task list.

What Is Automation and Robotics?

Automation is the use of technology in the performance of a function with minimum human interference, while robotics looks into the building of machines that can conduct complicated activities. The two provide the basis from which Industry 4.0 springs-a movement toward smart, connected systems.

Application across Industries

1. Manufacturing: Robots revolutionize assembly lines by undertaking repetitive work with accuracy whilst minimizing errors and enhancing productivity.

2. Healthcare: Robotic surgery and automated diagnostic tools facilitate better patient outcomes and quicker recovery times.

3. Logistics: Automated warehouses and delivery drones are smoothing the supply chain and ensuring a quicker delivery time.

4. Retail: AI-empowered robots enhance customers' experiences through inventory management to assist on the floor.

Benefits of Automation and Robotics

Efficiency rises: Tasks are completed faster and with greater accuracy.

Reduced costs: Cuts in labor costs, while wastage is minimized, consequently improve the margin of profit.

Enhanced safety: Robots are used to perform hazardous tasks meaning fewer accidents in the workplace.

The future of automation

As artificial intelligence and management learning continue to evolve, the capabilities of automation and robotics have a heavy possibility of shifting upward even more. These technologies would not only transform industries but create more opportunities in such fields as autonomous vehicles, smart homes, and customized services.

Through automation and robotics, firms would position themselves to fulfill yet another upsurge in consumer demand amidst intensified competition and earlier than later bring in a smarter tomorrow.

3. Quality Control Technology:

Rein venting Higher Perfection in Manufacturing

Quality control technology is revolutionizing industries through ensuring that a product meets the highest standards. Advances in automation, artificial intelligence (AI), and data analytics now help companies find defects, improve efficiencies, and minimize waste as they never did before.

The Role of AI and Automation

Quality control systems based on AI make use of machine learning algorithms to find inconsistencies in their products. Automated inspection systems, armed with high-resolution cameras and sensors, inspect for defects in real-time, eliminating human error while improving precision. The technology finds its wide applications in automotive, electronics, and pharmaceuticals, among others.

Data-Driven Quality Control

Modern-day quality control heavily relies on big data and predictive analytics. By analyzing historical data gathered over the years, a manufacturer has the ability to spot the trends, predict defects, and optimize production processes. It prevents inconsistencies, which is one of the main reasons companies opt for giving a proactive approach for quality.

Every Advanced QC System Operates:

Higher Efficiency: Automated inspections will allow maintenance by minimizing the downtime of the process and will fast-track operations.

Cost Efficiency: If a defect is detected at an early stage, an expensive recall and rework operation can be averted.

Improved Customer Satisfaction: Augmenting brand confidence and loyalty through quality products.

Regulatory Compliance: Ensuring all products abide by standards avoids legal trouble.

Future of Quality Control Technology

The future of quality control will nestle into promenades endowed with the most scholarly IoT-enabled sensors, blockchain fulfillment and traceability, and predictive maintenance decidedly actuated by AI. In times to come, businesses with smart quality control systems will grant themselves an upper hand in the market.

Quality control technology, therefore, is not something that can be sidelined; it has already become mandatory for businesses that dare to achieve perfection. Taking on these innovations will not hasten processes but also reduce costs and ensure good quality.

Conclusion

The concluding summary incorporates conclusions drawn from all six chapters.

Industrial technology is revolutionized modern industries through the infusion of automation, robotics, AI, and IoT to improve efficiency, precision, and sustainability. Smart manufacturing, 3D printing, and digital twin technology are also boosting innovations for sustainability and cybersecurity for longevity.

Automation and robotics are offering improvements in different sectors, including manufacturing, healthcare, and logistics. In addition to trimming costs, efficiency and safe work environments will be its hallmarks. AI-driven quality control systems involve big data analytics to minimize variability and ensure compliance with industry norms. This translates into higher customer satisfaction and reduced costs.

As industrial technology keeps evolving, companies need to adapt to remain competitive. Intelligent, connected, and eco-friendly manufacturing solutions will dominate the future, which among other things emphasizes efficiency, security, and innovation. These companies that are opening themselves to the changes will kindle the strategic transformation process in the constantly changing digital landscape.

Enjoyed this post? Stay tuned for more!

At TechTalks and TechVibes, we bring you the latest insights, trends, and deep dives into the world of technology. Whether it's gadgets, software, AI, or cybersecurity, we’ve got you covered!

Visit us at [https://techtalksandtechvibes.blogspot.com/?m=1] and follow us for more tech vibes!

Comments

Post a Comment